MODEL 3560 Bi-Axial or Axial Averaging

Extensometers

A single integral unit provides simultaneous lateral (transverse) strain and averaged axial strain measurement. The unit is also available as an averaged axial extensometer alone.

This extensometer is ideally suited for testing anisotropic materials such as advanced composites as well as for general purpose tests like determining Poisson's ratio. The Model 3560BIA uses a design unique to Epsilon, where the knife edges remain parallel during the displacement. This approach greatly reduces crosstalk between axes and allows use on round or flat specimens with equal ease. These extensometers are very easy to mount. Integral springs hold the unit on the test sample. The parallel multiple flexure design makes these units very durable.

The Model 3560AVG reads axial strain only, as a single averaged output. It may also be supplied with two independent outputs, one measurement from each side of the specimen. This set-up is most commonly required when an indication of specimen bending is desired. The second version, the Model 3560BIA, includes both the averaged axial strain and the transverse strain. Again, this may also be configured as dual independent axial readings, which results in a three channel extensometer.

The Model 3560 extensometers are strain gaged devices, making them compatible with any electronics designed for strain gaged transducers. Most often they are connected to a test machine controller. The signal conditioning electronics for the extensometer is typically included with the test machine controller or may often be added. In this case the extensometer is shipped with the proper connector and wiring to plug directly into the electronics. For systems lacking the required electronics, Epsilon can provide a variety of solutions, allowing the extensometer output to be connected to data acquisition boards, chart recorders or other equipment.

Features

- Multiple sets of dual flexures and mechanical stops allow testing through failure and provide a rugged unit.

- Full bridge, 350 ohm strain gaged design for compatibility with nearly any test system.

- Standard units meet existing ASTM class B-1 requirements for accuracy in tension. A calibration certificate is included. ISO 9513 class 0,5 calibrations are available upon request. All standard units have linearity readings of 0.15% or better in the transverse direction.

- Rugged, dual flexure design for improved performance.

- Includes high quality foam lined case and spare set of tool steel knife edges.

- Knife edge mounting and parallel displacement allows mounting on round or flat specimens. Much easier to mount than designs using conical points (especially on thin flat specimens and round ones).

- Self-supporting on the specimen.

- High accuracy and minimal crosstalk between channels.

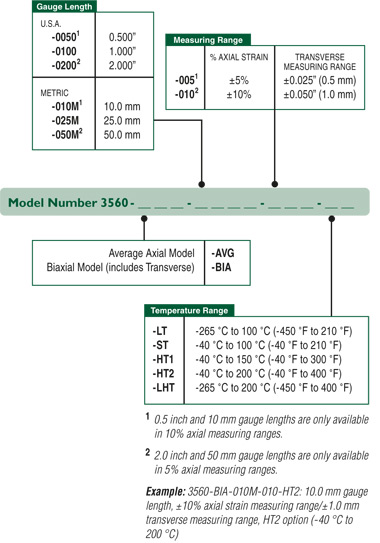

Model 3560 Available Versions: ANY combination of gauge length, measuring range and temperature range listed below is available.

![]() CERTIFIED

CERTIFIED

Specifications

Excitation: 5 to 10 VDC recommended, 12 VDC or VAC max.Output: 2 to 4 mV/V, depending on model

Linearity: ≤0.15% of full scale measuring range, depending on model

Temperature Range: Standard (-ST) is -40 °C to +100 °C (-40 °F to 210 °F)

Cable: Integral, ultra-flexible cable, 8 ft (2.5 m) standard

Specimen Size: Works with samples 0.1 to 1 inch width or diameter (2.5 mm to 25 mm)

Operating Force: 30 to 50 g typical

Crosstalk: Less than 0.5%

Options

- Connectors to interface to nearly any brand test equipment

> Shunt Calibration

> Specialty Knife Edges