MODEL 3550 Axial/Torsional Extensometers

Designed for simultaneously measuring axial and torsional deflections on specimens tested in axial/torsional machines.

The Model 3550 extensometer is most often used on round specimens tested in bi-axial test machines capable of simultaneous axial and torsional loading. The extensometer is often customized for particular applications. All units are capable of bi-directional displacement, so they may be used for cyclic testing under fully reversed loading conditions. The standard sized model is self-supporting on the specimen, and works on specimens from 0.375 to 1.000 inches (9.5 to 25.4 mm) diameter. The conical point contacts included with the extensometer are made from tungsten carbide. Their unique design directly measures the surface shear strain angle, which allows operation on a wide range of specimen diameters without changing calibration.

All models are designed specifically to minimize crosstalk between axes and to provide high accuracy measurements. All feature the dual flexure design common to other Epsilon extensometers.

Available options cover temperature ranges from -265 °C to 200 °C (the standard temperature range is -40 °C to 100 °C). Both inch and metric versions are available. A wide range of gauge length and measuring ranges are available. Because these transducers are often used for specialized tests, contact Epsilon with your specific test needs.

The Model 3550 extensometers are strain gaged devices, making them compatible with any electronics designed for strain gaged transducers. Most often they are connected to a test machine controller. The signal conditioning electronics for the extensometer is typically included with the test machine controller or may often be added. In this case the extensometer is shipped with the proper connector and wiring to plug directly into the electronics. For systems lacking the required electronics, Epsilon can provide a variety of solutions, allowing the extensometer output to be connected to data acquisition boards, chart recorders or other equipment.

Features

- Full bridge, 350 ohm strain gaged design for compatibility with nearly any test system.

- Standard units meet existing ASTM class B-1 requirements for accuracy in axial measuring range. A calibration certificate is included. ISO 9513 class 0,5 calibrations are available upon request. All standard units have linearity readings of 0.20% or better in torsion.

- Rugged, dual flexure design for strength and improved performance. Much stronger than single flexure designs, this also allows cyclic testing at higher frequencies.

- Includes high quality foam lined case.

- Self-supporting on the specimen.

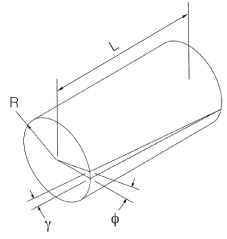

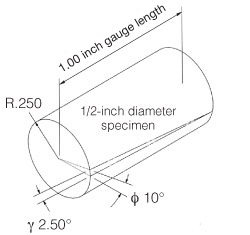

Epsilon’s axial/torsional extensometer was designed to directly measure the shear strain, γ, shown in the figure. This design allows the correct determination of the shear strain without having to know the radius of the specimen being tested, R1.

The shear strain is related to the angle of twist (a commonly referenced parameter in torsion testing), φ, by the following relationship:

![]()

For extensometers that measure φ directly instead of γ, corrections need to be made for every different specimen diameter tested and for axial strain to correctly determine the shear strain.

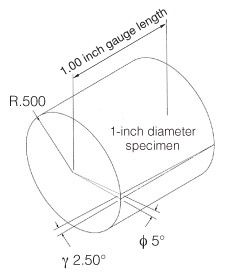

The two examples below show the variation of the angle of twist versus a change in specimen diameter relative to the constant resulting shear strain:

![]() CERTIFIED

CERTIFIED

Specifications

Excitation: 5 to 10 VDC recommended, 12 VDC or VAC max.Output: 2 to 4 mV/V, nominal, depending on model

Linearity: ≤0.15% of full scale measuring range, depending on model

Temperature Range: Standard (-ST) is -40 °C to +100 °C (-40 °F to 210°F)

Cable: Integral, ultra-flexible cable, 8 ft (2.5 m) standard

Operating Force: <30 g typical

Crosstalk: Less than 0.5%

Options

- Connectors to interface to nearly any brand test equipment

> Shunt Calibration

> Model 3590AT Axial/Torsional Calibrator