- The new version of Epsilon’s robust, cross-flexure design (introduced in May 2009) provides higher measuring ranges with much shorter extensometer arm lengths–all with much greater low strain performance.

- Operation of these, and all of Epsilon’s extensometers, are verified to either ASTM E83 or ISO 9513 standards using in-house calibration systems that are calibrated with Epsilon’s laser interferometer system.

- With Epsilon’s 20+ year history of service to the materials testing community, you know we will be there to stand behind our products when your critical application requires it.

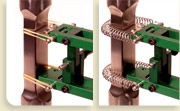

Optional rubber band and spring attachment options included with Model 3442 and 3542

Standard quick attach wire forms included for round and flat samples

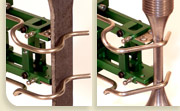

Model 3542 mounted on a D695 compression fixture for composite materials

MODEL 3542 Axial Extensometers

General purpose extensometers for axial tensile, compression, and cyclic testing. Gauge lengths from 0.5 to 2 inches (and 10 to 80 mm) and full scale measuring ranges from 5% to 100% strain.

These extensometers are designed for testing a wide range of materials, including metals, plastics, composites and ceramics. All will work in both tension and compression. The dual flexure design makes them very rugged and insensitive to vibrations, which permits higher frequency operation.

They come standard with Epsilon's quick attach kit, making it possible to mount the extensometer on the test specimen quickly and easily with one hand. The quick attach kit can be removed, allowing mounting of the extensometer with springs or rubber bands.

The Model 3542 extensometers are strain gaged devices, making them compatible with any electronics designed for strain gaged transducers. Most often they are connected to a test machine controller. The signal conditioning electronics for the extensometer is typically included with the test machine controller or may often be added. In this case the extensometer is shipped with the proper connector and wiring to plug directly into the electronics. For systems lacking the required electronics, Epsilon can provide a variety of solutions, allowing the extensometer output to be connected to data acquisition boards, chart recorders or other equipment.

For gauge lengths 4 inches or greater (100 mm) see Model 3542L.

Features

- May be left on through specimen failure.

- Full bridge, 350 ohm strain gaged design for compatibility with nearly any test system.

- All models can measure in both tension and compression and can be used for cyclic testing.

- Mechanical overtravel stops in both directions.

- Cable stops are used for overtravel protection where required. Epsilon's cable stops are contained fully between the arms of the extensometer, and do not hang below where they can interfere with fixturing – especially during compression testing.

- Standard units meet existing ASTM class B-1 requirements for accuracy. A calibration certificate is included. ISO 9513 class 0,5 calibrations are available upon request.

- Hardened tool steel knife edges are easily replaced. A spare set comes with every extensometer.

- High and low temperature options extend operation from as low as -265°C (-450 °F) to +200 °C (400 °F).

- Includes high quality foam lined case.

- Replaceable arms and spacers for ease of repair. This also allows changing the gauge length for different test requirements.

- Rugged, dual flexure design for strength and improved performance. Much stronger than single flexure designs, this also allows cyclic testing at higher frequencies.

- Standard quick attach kit allows one hand mounting to specimens.

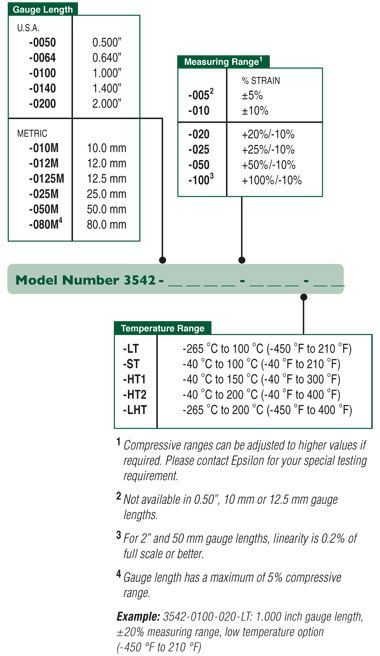

Model 3542 Available Versions: ANY combination of gauge length, measuring range and temperature range listed below is available, except as noted. Other configurations may be available with special order; please contact Epsilon to discuss your requirements.

![]() CERTIFIED

CERTIFIED

Specifications

Excitation: 5 to 10 VDC recommended, 12 VDC or VAC max.Output: 2 to 4 mV/V, nominal, depending on model

Linearity: 0.10% to 0.15% of full scale measuring range, depending on model

Temperature Range: Standard (-ST) is -40 °C to +100 °C (-40 °F to 210 °F)

Cable: Integral, ultra-flexible cable, 8 ft (2.5 m) standard

Standard Quick Attach Kit: Fits round samples up to 1.0 inch diameter (25 mm)and flats to 0.5 inch thick by 1.25 inch wide (12 mm by 31 mm)

Operating Force: 30 g typical

Options

- Quick attach kit wireforms for large specimens

- Adapter kits to change gauge lengths

- Connectors to interface to nearly any brand test equipment

- Special coatings and stainless steel knife edges available for biomedical tests.

> Shunt Calibration

> Specialty Knife Edges