- Epsilon designed and built the world’s first fully separable, strain gaged axial extensometer.

- The 3543 is ideal for rebar testing.

- Model3543 Has over a decade of proven performance in the harshest testing environments.

- Provides the necessary performance to successfully record strain on some of the most mechanically demanding specimens.

- For applications where the ruggedness of the extensometer is crucial, the Model 3543 has proven itself time-and-time again.

- With Epsilon’s 20+ year history of service to the materials testing community, you know we will be there to stand behind our products when your critical needs requires it.

Special Model 3543 with ability to work on test samples that twist up to 15° during the test

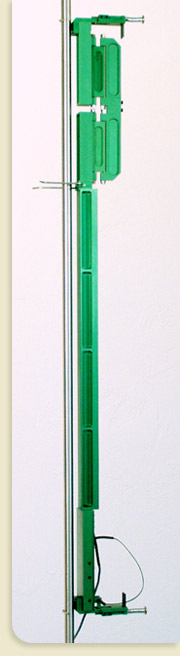

MODEL 3543 Long Gauge Length Extensometers

This model is available in gauge lengths from 2 inches (50 mm) and larger, with measuring ranges up to 4 inches (100 mm). It is a uniquely designed unit that may be left on through specimen failure. These extensometers are widely used where long samples are required. They are ideal for testing steel re-bar, weld joints, and wire materials.

With over 15 years of proven reliability in the world's most demanding testing environments, Model 3543 extensometer is designed to survive in those applications where standard axial extensometers would not. Designed by Epsilon, the Model 3543 was created to survive specimen failure by separating into two halves, thus preventing permanent damage to the module body. During operation, the upper half of the extensometer pulls out of the main body. Tapered measuring beams activate strain gaged flexures within the unit. This unique design allows long measuring ranges, yet retains compatibility with electronics for strain gaged transducers. These models offer high accuracy and are light weight but rugged, with low operating force. They are tension only units.

The units have hardened tool steel knife edges. Standard quick attach wires provided with the extensometer work on flat specimens up to 0.5 x 1.25 inch (12 x 31 mm) and on rounds up to 1 inch (25 mm) diameter. Optional quick attach kit wire forms are available for use on larger samples. See Model 3542L for long gauge lengths with smaller measuring ranges.

The Model 3543 extensometers are strain gaged devices, making them compatible with any electronics designed for strain gaged transducers. Most often they are connected to a test machine controller. The signal conditioning electronics for the extensometer is typically included with the test machine controller or may often be added. In this case the extensometer is shipped with the proper connector and wiring to plug directly into the electronics. For systems lacking the required electronics, Epsilon can provide a variety of solutions, allowing the extensometer output to be connected to data acquisition boards, chart recorders or other equipment.

Features

- Specifically designed to withstand testing through failure for specimens with rough or non-uniform surfaces such as rebar. The unit is designed so that the two halves of the extensometer come apart to prevent damage at specimen failure.

- Designed for non-reversed tension only testing. This model is not intended for strain control, cyclic or compressive testing.

- Full bridge, 350 ohm strain gaged design for compatibility with nearly any test system.

- All standard units meet ASTM class B-2 requirements for accuracy. Suitable for measuring plastic deformation and elongation to failure. For modulus and yield strain, a 3542 is required.

- Hardened tool steel knife edges are easily replaced. A spare set comes with every extensometer.

- High temperature options extend operation to +150 °C (300 °F).

- Includes high quality foam lined case.

- Replaceable arms and spacers for ease of repair. The optional gauge length spacers allow the gauge length of the extensometer to be easily increased for different testing requirements.

- Rugged design for reliable testing.

- Standard quick attach kit for quick mounting to specimens.

Model 3543 Available Versions: ANY combination of gauge length, measuring range and temperature range listed below is available, except as noted. Intermediate and longer gauge lengths are easily attained by adding gauge length spacers.

![]() CERTIFIED

CERTIFIED

Specifications

Excitation: 5 to 10 VDC recommended, 12 VDC or VAC max.Output: 2 to 4 mV/V nominal, depending on model

Linearity: ≤0.15% of full scale measuring range

Temperature Range: Standard (-ST) is -40 °C to +100 °C (-40 °F to 210 °F)

Cable: Ultra-flexible cable, 8 ft (2.5 m) standard

Standard Quick Attach Kit: Fits round samples up to 1.0 inch diameter (25 mm) and flats to 0.5 inch thick by 1.25 inch wide (12 mm by 31 mm)

Operating Force: 125 g typical

Options

- Quick attach kit wireforms for large specimens

- Spacers to change gauge lengths

- Connectors to interface to nearly any brand test equipment

- The 3543 is available with a twist option for use in applications where specimen twisting greater than 3° is expected. The 3543TW option can accommodate up to 15° of twist.

> Shunt Calibration

> Specialty Knife Edges