Back to High Temperature Overview

- Epsilon began production of our new, fourth generation probe design for the uncooled, high temperature axial extensometer in December 2009, and with this introduction, brought the greatest performance ever for these unique, high temperature models.

- The Model 3555 provides unparalleled performance in demanding high temperature applications where the complete extensometer must be exposed to the high temperature environment.

This product has

been replaced by

Model 7642.

MODEL 3555 High Temperature

Un-Cooled Extensometers (540 °C)

For use in environmental chambers where the entire extensometer must be exposed to elevated temperatures. These capacitive extensometers may be used up to 540 °C (1000 °F) without any cooling.

These extensometers use a high temperature capacitive sensor and do not require any cooling. They will operate up to the maximum temperature limit of most environmental chambers used in materials testing. The Model 3555 is ideal for testing composites, metals and high temperature polymers in tensile, compression or cyclic testing. All units can be displaced in both compression and tension.

The extensometer comes with the Model 3603 signal conditioner. The output is an analog DC voltage, factory calibrated with the extensometer to 0 to 10 VDC typically.

They are readily interfaced with most existing test controllers, and may be directly connected to data acquisition systems and chart recorders. Bringing the signal into a spare DC input channel (or external input) on the test controller allows the extensometer to be used for strain controlled tests like low cycle fatigue.

Features

- May be left on through specimen failure.

- Capacitive signal conditioner and power supply included. Provides high level DC voltage output with lowe noise. Easily interfaced to test controllers, data acquisition boards and chart recorders.

- Shipped fully calibrated with electronics (traceable to NPL (UK)) with user specified voltage output.

- All models can measure in both tension and compression and can be used for cyclic testing.

- Mechanical overtravel stops in both directions.

- All standard units meet existing ASTM class B-1 and ISO 9513, class 0,5 requirements for accuracy.

- Hardened tool steel knife edges are easily replaced. A spare set comes with every extensometer.

- Includes high quality foam lined case and a spare set of knife edges.

- Rugged, dual flexure design for strength and improved performance. Much stronger than single flexure designs, this also allows cyclic testing at higher frequencies.

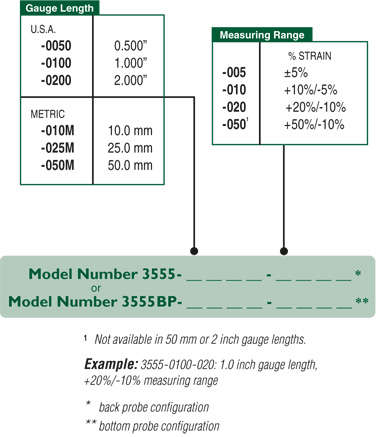

Model 3555 Available Versions: ANY combination of gauge length, measuring range and temperature range listed below is available, except as noted. Other configurations may be available with special order; please contact Epsilon to discuss your requirements.

Specifications

Input: Includes power supply for your country (specify)Output: User specified, +/-5 VDC or +/-10VDC typical

Linearity: ≤0.15% of full scale measuring range

Temperature Range: Elevated temperature use to 540°C (1000°F)

Cable: Triaxial ceramic fiber insulated cable 2 ft (0.6 m) plus 10 ft (3 m) room temperature extension cable

Standard Quick Attach Kit: Fits round samples up to 0.5 inch diameter (12 mm) and flats to 2.0 inches (50 mm) wide for thicknesses up to 0.25 inches (6.35 mm) and 0.75 inches (19 mm) wide for thicknesses between 0.25 (6.35 mm) and 0.50 inches (12.5 mm).

Operating Force: <30 g typical

Environment: Recommended for elevated temperature testing in air or some other gases

Options

- Adapter kits to change gauge lengths

- Connectors to interface to nearly any brand test equipment

- Bottom or back mounted probe

> VREF Module

> Specialty Knife Edges

_extensometer.jpg)