Back to High Temperature Overview

Specify rod tip style desired. Available choices shown above.

Straight chisel tips are the most versatile, since they can be used with round or flat specimens.

NOW AVAILABLE BY SPECIAL ORDER ONLY.

This product has been replaced by Model 3549.

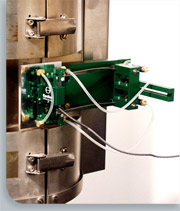

MODEL 3548 High Temperature Furnace Extensometers (1200°C or 1600°C)

High temperature extensometers for use in split type materials testing furnaces. Water-cooled and furnace bracket mounted, these are for use to 1200 °C (2200 °F). The high temperature option allows use to 1600 °C (2900 °F).

These extensometers mount on a water-cooled bracket mounted on the furnace side cut-out or with other support brackets. The standard temperature version (to 1200 °C) is supplied with high purity alumina rods. The high temperature option is furnished with alpha grade silicon carbide rods. Rods are made to order to the length required for your furnace. Mounting brackets may be integrated with the furnace cut-out. Epsilon can also provide optional load frame mounting brackets to fit your test frame.

The Model 3548 extensometers are strain gaged devices, making them compatible with any electronics designed for strain gaged transducers. Most often they are connected to a test machine controller. The signal conditioning electronics for the extensometer is typically included with the test machine controller or may often be added. In this case the extensometer is shipped with the proper connector and wiring to plug directly into the electronics. For systems lacking the required electronics, Epsilon can provide a variety of solutions, allowing the extensometer output to be connected to data acquisition boards, chart recorders or other equipment.

Features

- May be left on through specimen failure.

- Full bridge, 350 ohm strain gaged design for compatibility with nearly any test system.

- All models can measure in both tension and compression and can be used for cyclic testing (LCF).

- Mechanical overtravel stops in both directions.

- Most standard units meet existing ASTM class B-1 and ISO 9513, class 0,5 requirements for accuracy. Rod length configurations can affect the final class rating. Measuring ranges greater than 50% will meet these class requirements in lower calibration ranges.

- All units come with either high purity alumina ceramic rods (1200 °C) or alpha grade silicon carbide rods (1600 °C).

- Rugged, dual flexure design for strength and improved performance.

- Includes high quality foam lined case and a spare set of ceramic rods.

- Versions available for use in vacuum environments (consult factory).

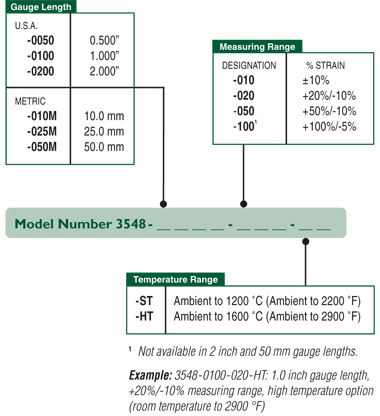

Model 3548 Available Versions: ANY combination of gauge length, measuring range and temperature range listed below is available, except as noted. Larger compressive ranges are available with special order.

![]() CERTIFIED

CERTIFIED

Specifications

Excitation: 5 to 10 VDC recommended, 12 VDC or VAC max.Output: 2 to 4 mV/V, nominal, depending on model

Linearity: ≤0.15% of full scale measuring range, depending on model

Temperature Range: Standard (-ST) is to 1200 °C (2200 °F), optional (-HT) 1600 °C (2900 °F)

Cable: Integral, ultra-flexible cable, 8 ft (2.5 m) standard

Contact Force: Adjustable up to 500 g

Operating Force: <30 g typical

Options

- Model 2050 constant temperature water re-circulating bath

- High temperature option (-HT suffix) for use to 1600°C

- Load frame mounting brackets

- Connectors to interface to nearly any brand test equipment

- Specify rod tip style desired. Available choice are: Straight chisel, vee chisel, conical tip

> Shunt Calibration