Back to Fracture Mechanics Overview

- Epsilon’s experts have many years of experience in the field of fracture toughness and fracture toughness testing. Please feel free to call and discuss your application requirements with them at any time.

- In-house frequency testing on small measuring range 3541 units (+2.5 mm/-1.0 mm) was successful to 150 Hz with a ±0.005 inch amplitude. At this level, there was no appreciable change in the noise level compared to lower frequencies.

- For longer measuring range units (+10 mm/-1.0 mm), 50 Hz was the maximum frequency that could achieved without excessive noise levels.

- Please feel free to contact Epsilon with your own high frequency questions and requirements.

- With verifiable calibration system accuracy and resolution sufficient to meet the requirements of ASTM fracture toughness gages, you can be assured that your COD gages will perform to your testing requirements.

- With Epsilon’s 20+ year history of service to the materials testing community, you know we will be there to stand behind our products when your critical needs requires it.

MODEL 3541 Fracture Mechanics Clip-On Gages

For fracture mechanics studies, these COD gages are in compliance with standardized test methods, such as ASTM E1820 for determination of fracture toughness properties of metallic materials.

These gages conform to the requirements of E1820 (the replacement for E813 and E1737) for JIC and R-curve determination. Special configurations are available to meet the requirements of ASTM E399 for fracture toughness (please consult the factory for these configurations). In addition, the modified groove design complies with E1820 tests where greater stability and accuracy results from the sharper groove root. Clip-on gages are used for a variety of fracture mechanics tests, including compact tension, arc shaped, disk shaped, bend specimens or other specimen geometries in compliance with ASTM and other standards organization’s test methods. Clip-on gages can be used directly on test specimens where the knife edges are integral with the test specimen or, alternately, with optional bolt-on knife edges mounted on the test specimen.

The Model 3541 extensometers are strain gaged devices, making them compatible with any electronics designed for strain gaged transducers. Most often they are connected to a test machine controller. The signal conditioning electronics for the extensometer is typically included with the test machine controller or may often be added. In this case the extensometer is shipped with the proper connector and wiring to plug directly into the electronics. For systems lacking the required electronics, Epsilon can provide a variety of solutions, allowing the extensometer output to be connected to data acquisition boards, chart recorders or other equipment.

Features

- Full bridge, 350 ohm strain gaged design for compatibility with nearly any test system.

- Fully enclosed gages to protect from accidental damage.

- All standard units meet existing ASTM requirements for accuracy.

- Special models available for ASTM E399 accuracy requirements.

- Sharp grooves per ASTM E1820 and E399 for improved stability when mounted.

- Includes high quality foam lined case.

- Maximum test frequency (2-200 Hz) varies according to gauge length, measuring range, test amplitude, and test requirements.

- For dadN testing or pre-cracking, where maximum frequency

(>50 Hz) is required, minimum measuring ranges are recommended. - For KIC/JIC testing, maximum test frequency is achieved with small measuring ranges and large gauge lengths.

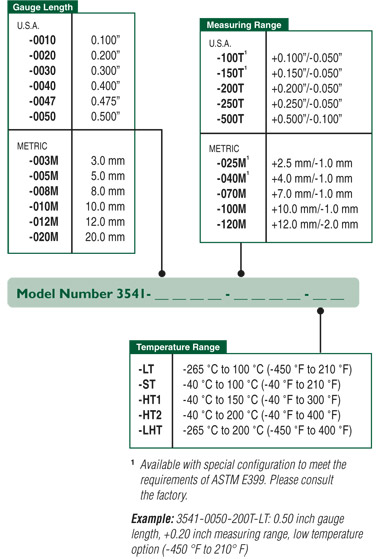

Model 3541 Available Versions: The following combinations of gauge length and measuring ranges listed below are available as standard, except as noted. All are available in any temperature range listed. Other configurations may be available with special order; please contact Epsilon to discuss your requirements.

![]() CERTIFIED

CERTIFIED

Specifications

Excitation: 5 to 10 VDC recommended, 12 VDC or VAC max.Output: 2 to 4 mV/V, nominal, depending on model

Linearity: 0.15% for measuring ranges less than 0.25 inch (6 mm), 0.20% for greater measuring ranges

Temperature Range: Standard (-ST) is -40 °C to +100 °C (-40 °F to +210°F)

Cable: Integral, ultra-flexible cable, 8 ft (2.5 m) standard

Operating Force: Exerts 2 to 3 lbs (9 to 14 N), depending on model

Options

- Connectors to interface to nearly any brand test equipment

- Available in special versions

- Bolt on knife edges

- Severe environment versions available

Special Models for Other Fracture Mechanics Testing

Special units are available for other fracture mechanics tests. For example, the photo to the right shows a gage for ASTM E1304, Standard Test Method for Plane-Strain (Chevron-Notch) Fracture Toughness of Metallic Materials. This example was produced for a 1 inch diameter bar, with 0.4 inches of measuring range. Its performance, design, and accuracy is an enhancement of the design recommended in E1304.

Special units are available for other fracture mechanics tests. For example, the photo to the right shows a gage for ASTM E1304, Standard Test Method for Plane-Strain (Chevron-Notch) Fracture Toughness of Metallic Materials. This example was produced for a 1 inch diameter bar, with 0.4 inches of measuring range. Its performance, design, and accuracy is an enhancement of the design recommended in E1304.

> Shunt Calibration